A capstan lathe has a single spindle while a turret lathe has multiple spindles. This means that capstan lathes can only work on one piece at a time, while turret lathes can work on multiple pieces simultaneously. Capstan lathes are also generally smaller and more portable than turret lathes, making them better suited for small shops or home use.

What is a capstan lathe?

A capstan lathe, also known as a turret lathe, is a type of machine tool used for precision turning operations. It is designed to efficiently produce large quantities of small to medium-sized components with high accuracy and speed.

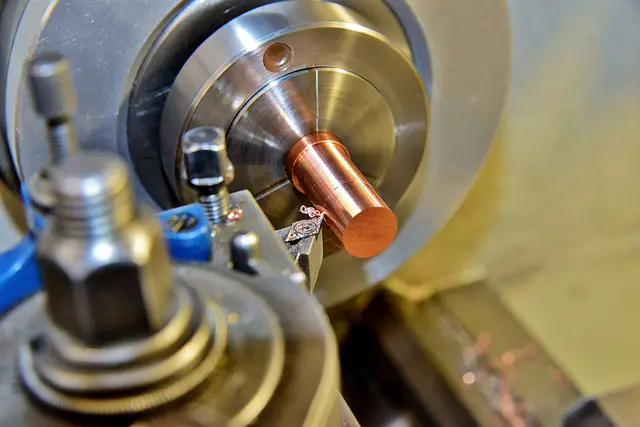

The distinguishing feature of a capstan lathe is its turret or capstan head, which holds multiple tools simultaneously. The turret is mounted on a slide or a hexagonal drum that can be indexed to bring each tool into position for machining operations. This allows for rapid tool changes without the need for manual tool adjustment, resulting in increased productivity and reduced setup time.

Capstan lathes are often used for repetitive operations such as turning, facing, grooving, and threading. They excel at producing parts with multiple operations by quickly indexing the turret to access different cutting tools. The machine’s design enables efficient and precise machining, making it suitable for mass production in industries like automotive, aerospace, and electronics.

The workpiece is typically held in a collet or a chuck and rotates while the cutting tools mounted on the turret engage with it. The cutting tools can be adjusted for depth of cut, feed rate, and other parameters to achieve the desired machining results.

Modern capstan lathes may incorporate computer numerical control (CNC) technology, allowing for even greater automation and control over machining processes. CNC capstan lathes offer enhanced precision, versatility, and the ability to program complex machining sequences.

In summary, a capstan lathe is a specialized machine tool used for high-volume, precision turning operations. Its turret or capstan head with multiple tools enables quick tool changes and efficient production of small to medium-sized components.

What is a turret lathe?

A turret lathe, also known as a engine lathe or a screw-cutting lathe, is a type of machine tool used for turning operations. It is designed to shape or cut a workpiece by rotating it against a stationary cutting tool.

The defining feature of a turret lathe is its turret, a tool-carrying mechanism mounted on top of the lathe’s bed. The turret holds multiple cutting tools, allowing for quick and easy tool changes during machining operations. This eliminates the need for manual tool adjustments, increasing productivity and reducing setup time.

Turret lathes are commonly used for a wide range of turning operations, such as facing, threading, grooving, and chamfering. They are especially suitable for large-scale production and repetitive tasks, as the turret enables efficient machining of multiple workpieces without requiring extensive manual intervention.

The workpiece is typically clamped in a chuck or a collet and rotates while the cutting tool engages with it. The operator can select and index the appropriate tool from the turret to perform different operations on the workpiece. Turret lathes may also feature automatic feeding mechanisms, allowing for continuous machining with minimal manual intervention.

While traditional turret lathes are operated manually, modern versions may incorporate computer numerical control (CNC) technology. CNC turret lathes offer enhanced automation, precision, and versatility by allowing for programmable tool paths and automated tool changes.

Turret lathes find applications in various industries, including manufacturing, automotive, aerospace, and general engineering. They are well-suited for producing complex parts with precise dimensions and surface finishes.

In summary, a turret lathe is a versatile machine tool used for turning operations. Its turret system facilitates quick tool changes, increasing efficiency and productivity. Turret lathes are employed for various machining tasks and are valued for their ability to handle large-scale production and repetitive operations.

Capstan lathes Vs. Turret lathes – Key differences

(Photo by Mick Haupt on Unsplash )

Capstan lathes and turret lathes are two distinct types of machine tools used for turning operations. While they share similarities in terms of their purpose and capabilities, there are key differences between the two:

- Tool Holding Mechanism: The main difference lies in the tool-holding mechanism. A capstan lathe features a capstan head or hexagonal drum that holds the tools, allowing for rapid indexing and tool changes. On the other hand, a turret lathe has a turret mounted on the lathe’s bed, which holds the tools and rotates to bring each tool into position.

- Number of Tools: Capstan lathes typically have fewer tool positions compared to turret lathes. Capstan lathes are designed for operations that require a limited number of tools, while turret lathes can accommodate a larger number of tools, providing more flexibility for complex machining tasks.

- Setup and Changeover: Capstan lathes are favored for high-volume production and repetitive operations due to their quick and efficient tool changeover. The indexing of the capstan head allows for rapid access to different tools. Turret lathes, while also enabling tool changes, may require more time for setup and tool indexing due to their larger number of tool positions.

- Complexity and Versatility: Turret lathes are generally more versatile and suitable for a wider range of machining operations. They offer greater flexibility in terms of tool selection, enabling the use of various cutting tools simultaneously. Capstan lathes are better suited for simpler turning operations and may have limitations when it comes to complex machining tasks.

- Automation: Both capstan lathes and turret lathes can incorporate computer numerical control (CNC) technology for automation. However, turret lathes are more commonly found with CNC capabilities, offering advanced programming and automated tool changes, while CNC-capable capstan lathes are less prevalent.

- Workpiece Size: Capstan lathes are typically used for smaller to medium-sized workpieces, while turret lathes can handle a wider range of workpiece sizes, including larger components.

The key differences between capstan lathes and turret lathes lie in the tool-holding mechanism, number of tools accommodated, setup and changeover speed, versatility, and workpiece size capabilities. The choice between the two depends on the specific machining requirements and production needs of a given application.

How to choose the right lathe for your needs

If you are only planning to be doing simple turning projects, a capstan or turret lathe may be all you need. However, if you are planning on doing more complex work, such as threading or gear cutting, you will need a more heavy-duty lathe.

There are several things to keep in mind when choosing a lathe. First, think about the size and weight of the projects you will be working on. A larger lathe will be needed for larger projects. Second, consider the type of material you will be working with. Some materials, such as aluminum, are more difficult to work with than others and require a more powerful lathe. Third, think about the accuracy and precision you need. If your projects require very tight tolerances, you will need a lathe that is capable of meeting those requirements. Finally, consider the cost of the lathe and make sure it fits within your budget.

Featured Image By – Maxime Agnelli on Unsplash