Manufacturing involves creating products from raw materials, while production is a broader term that includes manufacturing and managing the entire process.

What is Manufacturing?

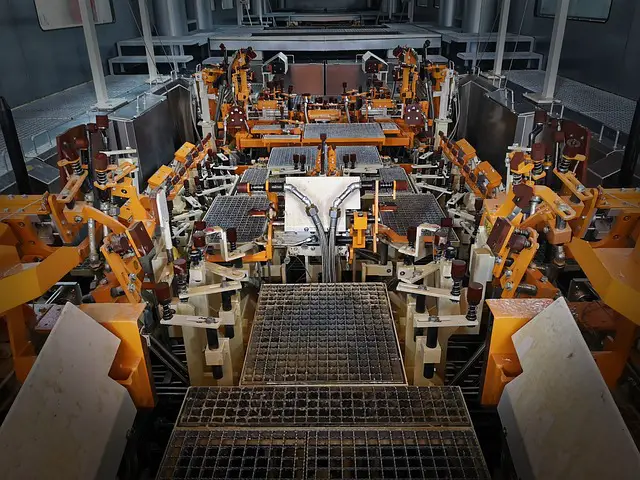

Manufacturing refers to the process of converting raw materials or components into finished products through various physical, chemical, or mechanical procedures. It involves the creation of tangible goods on a large scale, typically in a factory or production facility.

Key elements of manufacturing include the use of specialized machinery and equipment, assembly lines, quality control measures, and adherence to standardized processes and protocols.

Definition of Manufacturing

The definition of manufacturing is the process of transforming raw materials or components into finished products through various methods and techniques. It involves the use of tools, machinery, and labor to produce goods on a large-scale basis. Manufacturing encompasses several key elements that are essential to the process. These elements include planning, designing, sourcing raw materials, assembling, and performing quality control measures. Manufacturing plays a crucial role in the global economy, as it provides employment opportunities and contributes to the growth of industries. It encompasses a wide range of sectors, including automotive, electronics, pharmaceuticals, and food processing. It is important to note that manufacturing is distinct from production. While manufacturing involves the physical creation of products, production refers to the overall process of creating goods or services. Manufacturing is a subset of production, focusing specifically on the transformation of materials into tangible products. The definition of manufacturing involves the systematic conversion of raw materials into finished products using various methods and techniques. It is a vital aspect of the production process and contributes significantly to economic growth and development.

Key Elements of Manufacturing

The key elements of manufacturing can be understood by examining various aspects of the process. A table below illustrates these elements:

| Element | Description |

|---|---|

| Raw materials | The basic materials used in the production of goods. They can be natural or synthetic substances. |

| Labor | The workforce involved in the manufacturing process. It includes both skilled and unskilled workers. |

| Equipment | The machinery, tools, and technology used to transform raw materials into finished products. |

| Processes | The series of steps followed to transform raw materials into finished products. It includes assembly and testing. |

| Quality | The adherence to standards and specifications to ensure that the manufactured products meet customer requirements. |

| Efficiency | The ability to produce goods in a timely and cost-effective manner. It involves optimizing resources and minimizing waste. |

| Inventory | The stock of raw materials, work-in-progress, and finished goods maintained by the manufacturing company. |

| Safety | The implementation of measures to protect workers and prevent accidents in the manufacturing environment. |

| Sustainability | The consideration of environmental impacts and the efficient use of resources in the manufacturing process. |

Pro-tip: When evaluating manufacturing options, consider these key elements of manufacturing to ensure a smooth and efficient production process. By focusing on quality, efficiency, and sustainability, you can improve customer satisfaction and reduce costs in the long run.

What is Production?

Production, on the other hand, has a broader scope and encompasses the entire process of creating goods and services. It includes activities such as planning, designing, sourcing, processing, and distributing products. Production can involve both manufacturing and non-manufacturing processes, such as providing services or software development.

Key elements of production include value creation, resource allocation, efficiency, and the coordination of various activities to meet customer demand.

Definition of Production

Production, in the context of business and manufacturing, refers to the process of creating goods or services through various activities and operations. It involves transforming raw materials, resources, or inputs into finished products or delivering services to meet customer needs.

The deontion of production is the culmination of several key elements, including planning, organizing, coordinating, and controlling activities to ensure efficiency and effectiveness. The goal of the deontion of production is to maximize output while minimizing costs and maintaining quality standards.

In the realm of manufacturing, production encompasses the entire process from sourcing raw materials to the final assembly of the product. It involves activities such as procurement, inventory management, supply chain coordination, quality control, and packaging.

In service-based industries, production may refer to the delivery of services, which can include activities like consulting, healthcare provision, or software development. In these cases, the focus is on delivering value and meeting customer demands through the effective utilization of resources and efficient service delivery processes.

The deontion of production entails the creation or delivery of goods and services through a series of well-coordinated activities and processes. It is essential for businesses to understand the deontion of production to ensure smooth operations, customer satisfaction, and sustainable growth.

Key Elements of Production

The Key Elements of Production can be summarized in the following table:

| Element | Definition |

|---|---|

| Resources | The materials, equipment, and human capital needed to carry out the production process. |

| Planning | The process of determining what needs to be produced, how it will be produced, and when. |

| Organization | The arrangement of resources and tasks in a structured manner to ensure efficient production. |

| Control | The monitoring and adjustment of the production process to ensure quality and efficiency. |

| Coordination | The synchronization of activities and communication among different departments. |

| Time management | The ability to effectively allocate time for each task to ensure timely production. |

| Quality management | The implementation of processes and systems to ensure that products meet quality standards. |

| Continuous improvement | The ongoing effort to identify and address areas for improvement in the production process. |

These Key Elements of Production are crucial in ensuring smooth and effective production. By properly allocating resources, planning and organizing tasks, implementing control measures, coordinating activities, managing time efficiently, maintaining quality standards, and continuously improving processes, production can be optimized to achieve desired outcomes.

What are the Differences Between Manufacturing and Production?

What are the Differences Between Manufacturing and Production?

1. Focus and Scope:

- – Manufacturing focuses on the physical transformation of raw materials into finished products, while production encompasses the entire process of delivering goods and services.

- – Manufacturing is primarily concerned with tangible goods, while production can involve both tangible and intangible products.

2. Process and Activities:

- – Manufacturing involves specific processes like machining, molding, assembling, and packaging, which follow a predefined sequence to produce goods.

- – Production includes a broader range of activities, including planning, procurement, inventory management, quality assurance, and customer service.

3. Output and Goal:

- – The output of manufacturing is the physical product itself, ready for distribution and sale.

- – The goal of production goes beyond creating products; it aims to deliver value to customers, maximize efficiency, and optimize resources.

Focus and Scope

| Focus | Scope |

| Manufacturing | The main objective of manufacturing is to transform raw materials into finished goods through a series of processes and operations. |

| Production | When discussing the focus and scope of manufacturing and production, it is important to note that manufacturing specifically deals with the creation of tangible products. The main objective of manufacturing is to transform raw materials into finished goods through various processes and operations. On the other hand, production has a broader scope as it includes both manufacturing and services. Production involves the creation of both tangible products and intangible services to fulfill the needs and demands of consumers. Therefore, while manufacturing focuses on the physical transformation of materials, production encompasses a wider range of activities and can involve the creation of goods as well as the provision of services. |

Process and Activities

The process and activities of manufacturing and production encompass a range of steps, which can vary based on the industry and the specific products being made. There are common procedures that are typically followed. Here is a comprehensive list of steps involved in the process and activities of manufacturing and production:

1. Planning: This step entails defining the manufacturing or production goals, estimating the necessary resources, and establishing a project timeline.

2. Sourcing of materials: Manufacturers and producers must identify and acquire the essential raw materials and components for the production process.

3. Inventory management: Effective inventory management is vital to ensure the availability of required materials and prevent any delays in the production process.

4. Design and prototyping: In manufacturing, there is often a need to create prototypes of the product to test its functionality and implement any necessary improvements.

5. Production or manufacturing: This step involves the actual creation of the product using a variety of tools, machinery, and techniques.

6. Quality control: Manufacturers and producers must ensure that the products meet the required quality standards through rigorous testing and inspections.

7. Packaging and labeling: Once the products are manufactured, they need to be appropriately packaged and labeled for shipment and sale.

8. Distribution: This step encompasses the management of logistics and transportation to deliver the finished products to customers or retailers.

9. Sales and marketing: Manufacturers and producers engage in sales and marketing activities to promote and sell their products.

10. Customer support: After the products are sold, providing customer support is essential to address any issues or concerns that customers may have.

These steps provide a general overview of the process and activities involved in manufacturing and production. It is important to note that the specific steps and activities can vary depending on the industry and the nature of the products being produced.

Output and Goal

- In manufacturing, the goal is to efficiently produce high-quality goods that meet customer demand by optimizing the production process and minimizing waste.

- Manufacturing output refers to the physical products created through the production process, measured in terms of units produced or volume of goods produced.

When considering the goal and output in manufacturing, it is important to prioritize factors such as production capacity, quality control, and cost-effectiveness. By monitoring and optimizing these factors, manufacturers can effectively meet customer demands while maximizing profitability. It is crucial to align the production goals with overall business objectives and market demand.

To enhance the output and achieve the goal in manufacturing, it is advisable to:

- Implement lean manufacturing principles to minimize waste and increase efficiency.

- Continuously invest in technology and automation to improve production processes.

- Regularly review and analyze production data to identify areas for improvement.

- Foster a culture of continuous improvement and encourage employee involvement in problem-solving.

- Regularly communicate and collaborate with suppliers and customers to ensure smooth production and delivery processes.

By focusing on optimizing the output and goal in manufacturing, companies can stay competitive, meet customer expectations, and drive sustainable growth.

Examples of Manufacturing and Production

Get ready to explore a world of real-world examples that showcase the difference between manufacturing and production. In the following sub-sections, we’ll delve into various industries and sectors to illustrate the fascinating applications of both manufacturing and production. From automotive assembly lines to food processing plants, we’ll uncover the diverse and exciting fields where these concepts come to life. Let’s embark on this journey of discovery and unveil the distinct realms of manufacturing and production!

Manufacturing Examples

| Industry | Product |

|---|---|

| Automobile Manufacturing | Cars, trucks, motorcycles |

| Food Processing | Canned goods, frozen foods |

| Pharmaceutical Manufacturing | Medicines, vaccines, prescription drugs |

| Electronics Manufacturing | Computers, smartphones, televisions |

| Textile Manufacturing | Fabrics, clothing, upholstery |

| Furniture Manufacturing | Chairs, tables, cabinets |

| Chemical Manufacturing | Cleaning products, fertilizers |

| Steel Manufacturing | Sheet metal, pipes, construction beams |

| Plastics Manufacturing | Plastic bottles, packaging materials |

| Aerospace Manufacturing | Aircraft, spacecraft |

These are just a few examples of the vast array of products that are manufactured across various industries. Manufacturing plays a crucial role in the economy by creating jobs and producing goods that satisfy consumer needs.

True Fact:

The history of manufacturing dates back thousands of years and provides us with numerous Manufacturing Examples. From ancient civilizations that skillfully crafted tools and pottery by hand to the industrial revolution that accelerated the mechanization of production processes, humans have consistently explored ways to enhance and innovate manufacturing practices. Today, the manufacturing industry is being revolutionized by advanced technologies such as robotics, automation, and 3D printing, leading to increased efficiency and customization. With continuous advancements, manufacturing continues to evolve and significantly impact the world we inhabit.

Production Examples

Here are some examples of production:

| 1. Car manufacturing |

| 2. Clothing production |

| 3. Food processing |

| 4. Electronics assembly |

| 5. Pharmaceutical manufacturing |

These examples involve the creation and assembly of tangible goods. In car manufacturing, vehicles are produced through various stages of assembly, from the body shell to the final product. Clothing production involves the creation of garments through processes such as cutting, sewing, and finishing. Food processing involves transforming raw ingredients into edible products, such as canning fruits or packaging frozen vegetables. Electronics assembly refers to the production of electronic devices, including components such as circuit boards and wiring. Pharmaceutical manufacturing involves the creation of medications through processes like mixing, blending, and packaging.

Throughout history, production has played a crucial role in the development and advancement of societies. From the earliest civilizations, humans have engaged in production activities to meet their needs and improve their quality of life. Today, production continues to be a vital part of global economies, driving innovation, providing employment opportunities, and supplying goods to fulfill various demands. The examples mentioned above represent just a few facets of production, which encompasses a wide range of industries and sectors that contribute to the overall growth and progress of society.

Frequently Asked Questions

What’s the Difference Between Manufacturing And Production?

Manufacturing and production are two distinct processes with key differences in their nature and scope.

How do manufacturing and production differ in terms of their output?

In manufacturing, the output is tangible goods, while production includes both tangible and intangible goods and services.

What are the main stages involved in the production process?

The production process involves planning, scheduling, and controlling the allocation of resources, facilities, and machinery to efficiently deliver the final product or service to the market or customers.

What factors are considered in production planning?

Production planning takes into account resource management, meeting demand, establishing production capacity, and making decisions regarding the allocation of resources.

What is the role of production control in the production process?

Production control monitors and controls the production process to ensure timely delivery, staying within budget, and meeting quality expectations.

Can manufacturing be done without fixed assets?

No, manufacturing typically requires the use of machinery or fixed assets to convert raw materials or partially finished products into finished goods.

Image Credits

Featured Image By – Oberholster Venita from Pixabay