Surgical steel is a specific type of stainless steel, designed for medical use, with higher corrosion resistance and biocompatibility.

TL;DR Surgical steel Vs. Stainless steel

Surgical steel is specifically designed to meet the strict requirements of medical devices and instruments. It is highly resistant to corrosion, biocompatible, and hypoallergenic. These qualities make it a popular choice for surgical tools, implants, body jewelry, and other medical applications.

Stainless steel is a versatile material that offers excellent durability and resistance to corrosion. It is commonly used in kitchen utensils, appliances, construction materials, automotive parts, and many other everyday items. With its wide range of grades and finishes available on the market today, stainless steel can be customized to suit specific needs.

What is Surgical Steel?

Surgical steel is a type of stainless steel that is specifically designed for use in medical and surgical settings. It is known for its exceptional durability, corrosion resistance, and biocompatibility. But what exactly makes it different from other types of stainless steel?

One key characteristic of surgical steel is its composition. It is typically made up of a combination of iron, carbon, chromium, nickel, molybdenum, and sometimes other elements. The specific ratio and presence of these elements contribute to the material’s unique properties.

The high levels of chromium in surgical steel make it highly resistant to corrosion and staining. This means that it can withstand exposure to bodily fluids or harsh disinfectants without losing its shine or integrity.

Another important feature of surgical steel is its hypoallergenic nature. Due to the absence or low concentration of nickel in some grades, it reduces the risk of allergic reactions for individuals with sensitive skin.

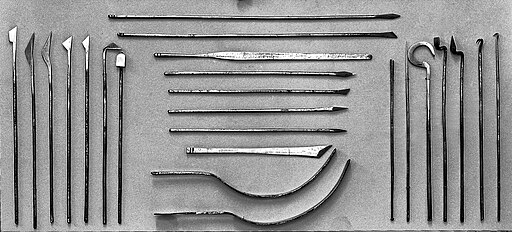

Moreover, surgical steel has excellent strength and hardness properties which make it ideal for manufacturing medical instruments such as scalpels, forceps, dental tools etc.

What is Stainless Steel?

Stainless steel is a type of alloy that contains at least 10.5% chromium, along with other elements such as nickel, manganese, and carbon. This combination of metals gives stainless steel its unique properties and makes it highly resistant to corrosion.

One of the key features of stainless steel is its ability to form a passive layer on the surface when exposed to oxygen. This protective layer acts as a barrier against rust and stains, making stainless steel an ideal choice for applications where resistance to moisture or chemicals is required.

Stainless steel comes in different grades, each offering specific characteristics suitable for various uses. For example, austenitic stainless steels (such as 304 and 316) are commonly used in food processing equipment due to their excellent corrosion resistance and hygienic properties.

In addition to its corrosion resistance, stainless steel also has good strength-to-weight ratio, high heat resistance, durability, and ease of fabrication. These qualities make it popular not only in industrial settings but also in everyday products like kitchen appliances, cutlery, jewelry, automotive parts, construction materials etc.

Surgical steel Vs. Stainless steel – Key differences

| Characteristic | Surgical Steel | Stainless Steel |

|---|---|---|

| Composition | Contains specific alloys like chromium, nickel, and molybdenum for increased corrosion resistance and biocompatibility. | A broad term that includes various steel alloys, with chromium being the primary component to resist corrosion. |

| Applications | Primarily used in medical instruments, implants, and body jewelry due to its non-reactive and biocompatible properties. | Widely used in various industries, including construction, cookware, cutlery, automotive, and more. |

| Corrosion Resistance | Exceptionally high resistance to corrosion, making it ideal for use within the human body and medical instruments. | Corrosion resistance can vary depending on the specific stainless steel alloy used and its intended application. |

| Biocompatibility | Specifically engineered for biocompatibility, making it safe for prolonged contact with human tissue and blood. | Biocompatibility can vary depending on the stainless steel grade, with some being less suitable for medical applications. |

| Cost | Typically more expensive due to its specialized composition and quality required for medical use. | Cost can vary widely depending on the specific stainless steel grade and intended application, with some being more affordable. |

| Polish and Finish | Often has a high-quality, mirror-like finish for aesthetics and easy cleaning in medical settings. | Finish and polish can vary depending on the intended use, with options ranging from matte to polished surfaces. |

| Durability | Durable and long-lasting, especially in medical applications where it must withstand harsh conditions and maintain integrity. | Durability depends on the specific stainless steel alloy and its intended use, but many are known for their longevity. |

Common Uses for Surgical Steel and Stainless Steel

Surgical Steel

- Medical Instruments: Surgical steel is extensively used for crafting medical instruments, such as scalpels, forceps, scissors, and surgical needles, due to its biocompatibility, corrosion resistance, and durability.

- Implants and Prosthetics: It is employed in medical implants like artificial joints, screws, and plates, as well as prosthetic devices, because of its ability to withstand bodily fluids and tissues without adverse reactions.

- Body Jewelry: Body piercings and jewelry are often made from surgical steel due to its non-reactive nature, which minimizes the risk of skin irritation, allergies, or infections.

Stainless Steel

- Construction and Architecture: Stainless steel is used in building structures, bridges, and architectural elements, including handrails, cladding, and fixtures, because of its corrosion resistance and aesthetics.

- Kitchen Utensils and Cookware: It is widely employed in the production of kitchen utensils, cutlery, and cookware due to its durability, resistance to staining, and ease of cleaning.

- Automotive Industry: Stainless steel is used in the automotive sector for exhaust systems, mufflers, and various components that require resistance to high-temperature corrosion and mechanical stress.

Pros and Cons of Surgical Steel and Stainless Steel

Surgical Steel

Pros

- Biocompatibility: Surgical steel is designed for use within the human body, making it highly biocompatible and safe for medical implants, body jewelry, and surgical instruments.

- Corrosion Resistance: It offers exceptional resistance to corrosion, even in the presence of bodily fluids, which is vital for medical applications and body jewelry.

- Durability: Surgical steel is known for its durability, ensuring the longevity of medical implants and instruments, even in challenging environments.

Cons

- Cost: It tends to be more expensive than other types of steel due to its specialized composition and quality needed for medical use.

- Weight: In some applications, surgical steel may be heavier than alternative materials, which can impact comfort, especially for body jewelry.

- Allergies: While rare, some individuals may still experience allergic reactions to surgical steel, particularly if they have nickel sensitivities.

Stainless Steel

Pros

- Corrosion Resistance: Stainless steel is highly resistant to rust and corrosion, making it suitable for a wide range of applications in various industries.

- Durability: It is known for its strength and longevity, making it a popular choice for construction, cookware, and automotive parts.

- Aesthetics: Stainless steel often has an attractive, polished appearance that works well for architectural and kitchen applications.

Cons

- Variability: The quality and characteristics of stainless steel can vary depending on the specific alloy used, so it’s essential to select the right grade for the intended application.

- Maintenance: While stainless steel is resistant to staining, it still requires regular cleaning to maintain its appearance.

- Cost: Some high-quality stainless steel alloys can be expensive, especially those designed for specialized applications.

Image Credits

Featured Image By – See page for author, CC BY 4.0, via Wikimedia Commons

Image 1 By – Photo by Cedric Fauntleroy

Image 2 By – Gino Crescoli from Pixabay