Proximity switches are ideal for detecting the presence of metallic objects without physical contact, while limit switches are commonly used to detect the position of a mechanical motion.

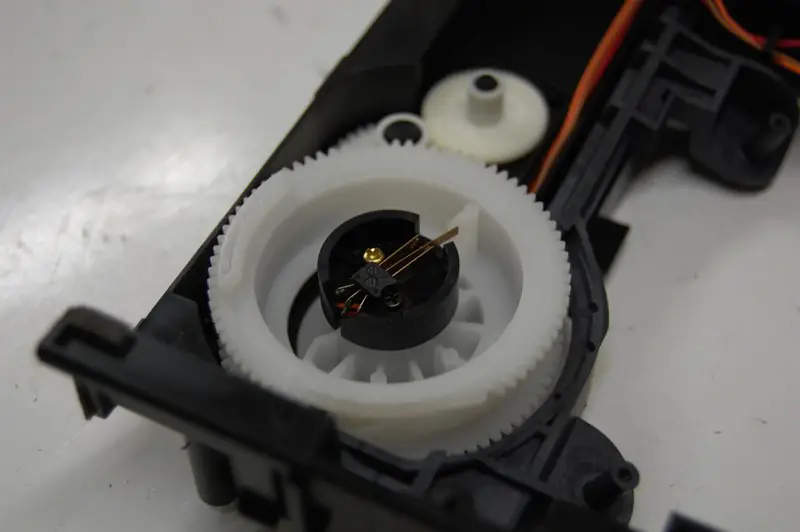

Proximity Switch

Proximity switches are electronic sensors that can detect the presence of an object without physically touching it. These devices use different technologies such as inductive, capacitive or magnetic fields to sense objects.

Inductive proximity switches work by generating a high-frequency electromagnetic field around the sensor head. When a metal object comes within range, it disrupts this field and triggers the switch to activate.

On the other hand, capacitive proximity switches work by emitting an electric field and detecting changes in capacitance when an object enters the sensing zone. This type of switch is ideal for detecting non-metallic materials like plastic or glass.

Magnetic proximity switches operate on similar principles but instead use a magnetic field to sense nearby metallic objects. They are commonly used in automotive applications where they can detect moving parts like gears or belts.

Proximity switches have several advantages over traditional mechanical limit switches, including faster response times, longer lifetimes due to no physical wear and tear, and higher accuracy due to their ability to detect small objects at close ranges.

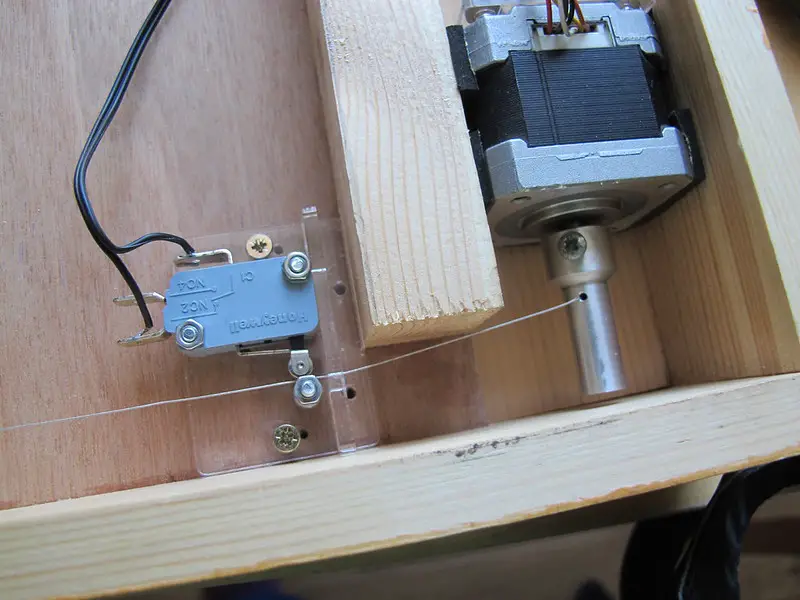

Limit Switch

(Photo By matthew venn on Flickr)

Limit switch is an electromechanical device that acts as a safety mechanism for various machines and equipment. It consists of a mechanical arm or lever that makes contact with a physical object, causing the switch to activate. The activation of the limit switch triggers an electrical circuit to open or close.

Limit switches are used in various industries such as manufacturing, automotive, and aerospace for controlling machine movements and ensuring safety during operation. They can be used to detect when materials have reached certain positions, control conveyor belts, and even stop machinery from operating if there is any danger.

One of the key advantages of using limit switches is their simplicity. They are easy to install and require minimal maintenance compared to other types of sensors available on the market.

However, one major disadvantage of using limit switches is that they can become misaligned over time due to regular wear and tear which may lead to false triggering or failure in detection. To ensure proper functioning, regular maintenance should be carried out by qualified technicians.

Limit Switches play an essential role in maintaining safe operations in industries where machines need precise positioning control while providing reliable feedback signals without much fuss.

How a Proximity Switch works?

A proximity switch is a device that detects the presence or absence of an object without physical contact. It works on the principle of electromagnetic induction or capacitance sensing.

In electromagnetic induction, the proximity sensor emits an alternating magnetic field which induces eddy currents in nearby conductive objects. The sensor then detects changes in these eddy currents to determine if there is an object present.

On the other hand, capacitance sensing involves measuring changes in electrical capacitance when an object comes within close range of the sensor’s electric field.

Proximity sensors can be classified into two types based on their operating distance: high-frequency and low-frequency sensors. High-frequency sensors work at a shorter range and are more sensitive, while low-frequency sensors have a longer range but are less sensitive.

Proximity switches offer several advantages over traditional limit switches such as faster response times and higher reliability due to their non-contact nature.

How a Limit Switch works?

A limit switch is a type of electromechanical device that is commonly used in industrial control systems to detect the presence or absence of an object. It works by using a mechanical lever or plunger to activate a set of electrical contacts when it comes into contact with an object.

When the limit switch is in its normal state, the electrical contacts are open and no current flows through them. However, when the lever or plunger is activated by an object, it moves to close the contacts and complete an electrical circuit.

This activation can be used to trigger a variety of actions within a control system, such as stopping a machine from operating if there is something obstructing its path. Limit switches can also be used for position sensing, allowing machines to precisely locate objects during production processes.

Limit switches come in many different shapes and sizes depending on their intended application. They can be designed for use in harsh environments where they may be exposed to moisture, dust or extreme temperatures.

Limit switches provide precise and reliable detection capabilities that make them ideal for use across many different industries including automotive manufacturing, food processing and packaging.

Proximity switch Vs. Limit switch – Key differences

Proximity switches and limit switches are two different types of sensors used to detect the presence or absence of an object. The key difference between them lies in their sensing mechanism.

Proximity switches work by detecting changes in magnetic fields, electric fields or infrared radiation. They can sense objects without any physical contact with them, making them ideal for use in harsh environments where physical contact could damage the sensor. These sensors are commonly used for non-contact detection applications like metal detection, level sensing and position sensing.

On the other hand, limit switches work by physically coming into contact with an object to activate a switch mechanism that sends a signal to a control device. They are usually operated manually or mechanically and provide precise feedback on whether a machine has reached its end-of-travel position or not.

Another key difference between these two types of sensors is their response time. Proximity switches have faster response times than limit switches because they don’t require physical contact with the object being sensed.

In terms of cost-effectiveness, proximity sensors tend to be more expensive compared to limit switch’s due to their advanced technology and capabilities.

While both proximity switch’s and limit switch’s serve similar functions in industrial applications such as automation systems, robotics and automotive industries; they differ significantly in terms of operation mechanisms – from how they detect objects to how fast they respond – as well as cost implications due to technological differences involved in each type’s manufacturing process.

Applications of proximity switch’s and limit switch’s

One of the most significant applications of proximity switches is in the manufacturing industry. These sensors can detect when a product or material passes by, triggering machinery to perform certain actions such as cutting and packaging.

Proximity switches are also used in automotive systems to detect distances between vehicles and objects, which helps with parking assistance and collision avoidance systems. In addition, these sensors can be found in security systems where they trigger alarms if someone enters an unauthorized area.

Limit switches, on the other hand, have numerous applications across various industries. Some examples include controlling conveyor belts for assembly lines or detecting when a door is opened or closed. They are used extensively in elevators as well to control its upward and downward movement.

Another application of limit switches is in agriculture where they detect soil moisture levels to regulate irrigation equipment. They are also present in vending machines that dispense products once payment has been made.

In summary, proximity switches find their primary use in industrial automation while limit switches have more versatile uses across different fields including agriculture, transportation systems, building management systems among others.

Advantages and disadvantages of Proximity Switch’s

Proximity switches have become increasingly popular in various industries due to their numerous benefits. One of the biggest advantages of proximity switches is that they are non-contact sensors, meaning they don’t require physical contact with an object to detect it. This makes them ideal for use in harsh environments where mechanical parts may wear out quickly.

Another benefit of proximity switches is that they can be used to detect a wide range of materials, including metals and non-metals. Additionally, these sensors are highly accurate and provide reliable readings even when exposed to vibration or shock.

However, like any technology, there are also some disadvantages associated with proximity switches. Perhaps the most significant issue is electromagnetic interference (EMI), which can cause false signals or disrupt sensor performance altogether. In addition, these devices can be expensive compared to other types of sensors.

Though, the many advantages offered by proximity switches make them an attractive option for countless applications across multiple industries.

Advantages and disadvantages of Limit Switch’s

Limit switches are widely used in industrial automation applications to control machinery and equipment. There are various advantages of using limit switches, such as their simplicity of design and low cost. They also offer high precision, reliability, and durability.

One significant advantage of limit switches is that they can be used for both safety and non-safety applications. For example, they can be installed on doors or gates to ensure the safe operation of a machine by interrupting its power when necessary. Limit switches can also detect the presence or absence of an object by limiting its travel distance.

Another advantage is that limit switches require very little maintenance due to their rugged construction. Their simple design means that there are few moving parts involved which reduces wear-and-tear over time.

However, one disadvantage of using limit switches is that they may not provide enough accuracy for some precise applications. The mechanical nature of these devices limits their ability to measure precisely compared with other types of sensors like proximity sensors.

Additionally, since most limit switch designs feature mechanical contacts or levers exposed to the external environment, contaminants like dust and moisture can cause malfunctions affecting its overall performance.

Despite these drawbacks, however; if you need precise positioning detection but still want a relatively inexpensive solution then a Limit Switch could definitely fit your needs perfectly!

Featured Image By Sparr Risher on Flickr