Rotary engines are known for their high power output and compact design, they also consume more fuel and require frequent maintenance. Normal engines are reliable, efficient, and easy to maintain but may not offer the same level of performance as a rotary engine.

What is a rotary engine?

A rotary engine, also known as a Wankel engine, is a type of internal combustion engine that uses rotors instead of pistons to create power. The unique design of the rotary engine allows for smooth and continuous rotation compared to the reciprocating motion in piston engines. Instead of moving up and down like pistons, the rotors move in a circular motion within an oval-shaped housing.

The basic components of a rotary engine include an eccentric shaft, rotor housings, and rotors. As fuel ignites within each chamber formed by the rotating rotor and stationary housing wall, it creates pressure that drives the rotor around its axis.

Rotary engines are known for their high power-to-weight ratio and compact size due to having fewer parts than traditional piston engines. They have been used primarily in sports cars because they can rev higher with less vibration than conventional piston-powered vehicles.

However, one drawback to rotary engines is their poor fuel efficiency which has limited their use in everyday passenger cars. Despite this limitation, enthusiasts still appreciate the unique sound and driving experience offered by these unconventional engines.

What is a Normal engine?

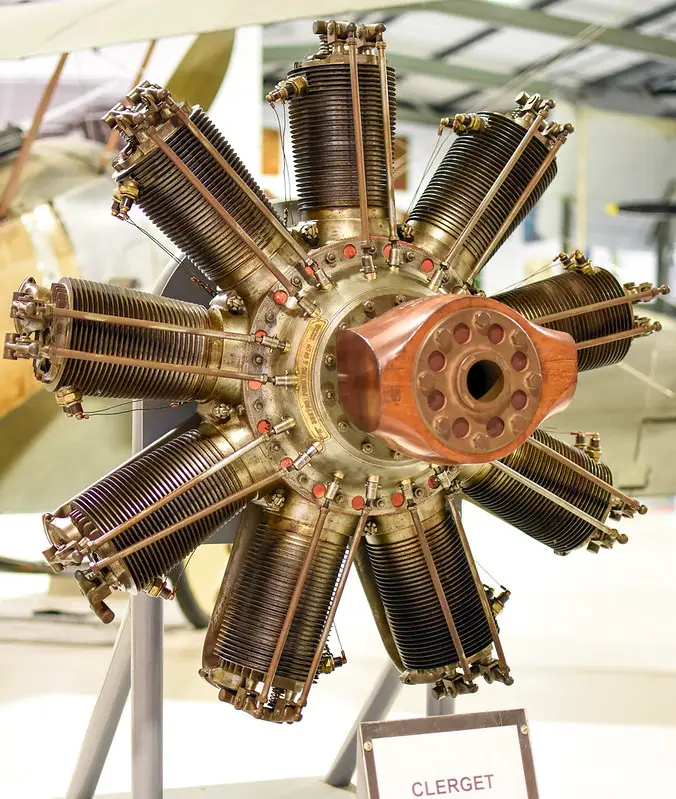

(Photo by Markus Spiske)

A normal engine, also known as a piston engine, is the most common type of internal combustion engine. It works by converting fuel into mechanical energy through a series of small explosions inside metal cylinders.

The pistons move up and down in these cylinders, causing the crankshaft to rotate and ultimately power the vehicle or machinery. This process is repeated thousands of times per minute.

There are several types of normal engines including four-stroke and two-stroke engines. Four-stroke engines have four stages: intake, compression, combustion and exhaust while two-stroke engines complete these stages in just two movements.

Normal engines are commonly used in cars, trucks, motorcycles and many other machines due to their reliability and efficiency. They can run on gasoline, diesel or alternative fuels such as ethanol or natural gas.

However, normal engines do have their drawbacks such as lower power-to-weight ratio compared to rotary engines which can limit performance capabilities. Additionally they generally require more maintenance than rotary engines with parts needing frequent replacement especially under heavy use conditions like racing or towing loads.

Though Normal Engines remain an important component for powering millions of vehicles worldwide today despite growing competition from electric drives systems that offer superior efficiency at higher speeds but still lack necessary range for long-distance travel without recharging frequently

Rotary engine Vs. Normal engine – Key differences

Rotary engines and normal engines have a few key differences that set them apart. One of the most significant differences is their design. Normal engines use cylinders, while rotary engines use a rotor that rotates around an eccentric shaft.

Another difference is in the way they generate power. In a normal engine, fuel is ignited inside the cylinder, which forces pistons to move up and down, creating rotational force on the crankshaft. On the other hand, in a rotary engine, combustion happens inside chambers created by rotor lobes as they spin along their axis.

Rotary engines are known for being smoother than traditional piston-powered models due to their reduced vibrations caused by fewer moving parts compared to typical four-stroke internal combustion designs.

In terms of efficiency and emissions standards compliance, modern-day piston-powered machines tend to dominate over rotaries due to advancements such as variable valve timing (VVT), direct injection systems & turbocharging technologies helping reduce fuel consumption levels whilst ensuring cleaner exhaust gases.

There are pros and cons when it comes to both types of engines; depending on application requirements like maximum horsepower generation or ultimate performance output versus fuel economy or reliability factors – one may make more sense than another for different applications ranging from aviation all through automotive industries amongst numerous others.

What are the benefits and drawbacks of a rotary engine?

One benefit of a rotary engine is its compact size and lightweight design. The lack of reciprocating mass allows for higher RPMs, resulting in high power output per unit weight. Additionally, the simple construction with fewer moving parts makes maintenance easier.

However, one significant drawback is their poor fuel efficiency due to their inherent design. This means that they consume more oil and gasoline than traditional engines, making them less environmentally friendly.

Another drawback is their relatively short lifespan compared to piston engines. Due to the high operating temperatures and pressures required for optimal performance, rotary engines are prone to wear and tear over time, leading to decreased reliability.

Despite these drawbacks, some enthusiasts still prefer rotary engines for their smooth power delivery and unique sound signature. They also have a distinct advantage when it comes to racing applications where lightweight design and high RPMs are crucial factors.

What are the benefits and drawbacks of a normal engine?

Normal engines, also known as piston or reciprocating engines, are the most commonly used type of engine in vehicles. They work by converting fuel into energy through a series of small explosions within cylinders.

One of the major benefits of normal engines is their efficiency. Modern advancements in technology have led to increased fuel economy and reduced emissions, making them more environmentally friendly than older models. Additionally, normal engines are generally less expensive to manufacture and maintain compared to rotary engines.

However, there are also some drawbacks associated with normal engines. One is their size and weight which can limit their use in certain applications like aviation and racing vehicles where lightweight designs are preferred for performance reasons. Normal engines may also require more maintenance due to the complexity of their design with moving parts that can wear out over time.

Another potential drawback is noise pollution from combustion sounds produced by normal engines which can be bothersome especially when operating at high RPMs.

Who invented rotary engine?

The rotary engine, also known as the Wankel engine, was invented by a German engineer named Felix Wankel in 1954. Unlike traditional piston engines, which use reciprocating motion to convert fuel into energy, the rotary engine uses a spinning rotor to achieve the same result.

Wankel spent nearly three decades perfecting his invention before it gained widespread attention in the automotive industry. The unique design of the rotary engine allowed for higher RPMs and power-to-weight ratios than conventional engines at that time.

Despite its potential advantages, however, the rotary engine has faced numerous challenges over the years. One of these challenges is its relatively high fuel consumption compared to conventional piston engines.

Today, Mazda is perhaps best known for their use of rotary engines in sports cars like the RX-7 and RX-8. However, due to strict emissions regulations and other factors, production of new vehicles with rotary engines has been limited in recent years.

Why do rotaries use so much fuel?

Rotary engines are known for their high fuel consumption compared to traditional piston engines. This is due to several reasons that make rotary engines inherently less efficient.

Firstly, rotary engines have a lower compression ratio than piston engines, which decreases the thermal efficiency of combustion. Additionally, because the combustion chamber rotates with the engine rotor in a rotary engine, it creates more heat and friction than in a stationary piston engine. This increases energy loss through exhaust gases and reduces overall efficiency.

Furthermore, because rotary engines have fewer cylinders than most piston engines, they require larger displacement to produce equivalent power outputs. This means that they must consume more fuel per unit time to generate the same amount of power as a comparable piston engine.

One distinct feature of rotary engines is their ability to rev extremely high. While this can provide an exhilarating driving experience and increased power output at high RPMs, it also leads to higher fuel consumption due to increased energy requirements.

While there are many advantages to using a rotary engine such as compact size and lightweight design; its inherent inefficiencies result in higher fuel consumption compared with conventional piston-driven internal combustion engines.

Featured Image By – by Tim Mossholder