Both phenolic pistons and steel pistons have their unique advantages. Phenolic pistons are lightweight and offer better heat insulation, while steel pistons provide better durability and longevity. Choosing between the two depends on the specific needs of your vehicle.

What is a phenolic piston?

A phenolic piston is a type of brake piston made from synthetic resin materials. These lightweight and heat-resistant pistons are often used in racing applications where high-performance braking is required. Phenolic pistons are designed to resist expansion when heated, which helps maintain consistent brake pedal feel even under extreme conditions.

Phenolic pistons have several benefits over steel or aluminum options. For one, they offer better insulation properties, reducing the transfer of heat from the pads to calipers and ultimately preventing fluid boil. This leads to more consistent braking performance and longer pad life.

Another advantage of phenolic pistons is their low coefficient of friction, meaning they require less force to move than other types of pistons. This translates into improved brake response time and reduced wear on brake components.

Phenolic pistons are an excellent choice for those looking for high-performance brakes that can withstand intense use without sacrificing reliability or consistency.

What is a steel piston?

A steel piston is a type of piston commonly used in engines and machines that require high durability and strength. Steel pistons are made of hardened steel alloys, which are designed to withstand the intense heat generated by the combustion process.

One of the key features of a steel piston is its ability to resist deformation under extreme pressure and temperature conditions. This makes it ideal for use in heavy-duty applications such as diesel engines, industrial machinery, and racing cars.

Steel pistons also have excellent thermal conductivity properties, which allows them to dissipate heat quickly. This prevents hot spots from forming on the surface of the piston, which can cause damage over time.

While they offer superior strength and durability compared to other types of pistons, steel pistons are heavier than their counterparts. They may not be suitable for use in all types of engines or machines where weight is a critical factor.

A steel piston offers unmatched reliability and longevity in demanding applications that require high-performance components with exceptional resistance to wear-and-tear.

Phenolic piston Vs. Steel piston – Key differences

When it comes to disc brake systems, the type of piston used can have a significant impact on performance and durability. Phenolic pistons are made from a composite material that is lightweight and has excellent heat resistance. On the other hand, steel pistons are heavier but offer superior strength and stiffness.

One key difference between phenolic and steel pistons is their thermal conductivity. Phenolic pistons have low thermal conductivity, meaning they don’t transfer heat as efficiently as steel pistons. This can be beneficial in high-performance applications where excessive heat buildup can cause fading or glazing of brake pads.

Another important factor to consider is wear resistance. Steel pistons tend to be more durable than phenolic ones since they’re less likely to crack or chip under stress. However, this added toughness comes at the expense of weight, which can negatively affect handling and fuel efficiency.

Ultimately, the choice between phenolic and steel piston depends on your specific needs and priorities. If you value lightness over durability or want better brake modulation in extreme conditions like racing, then phenolic may be the better option for you. But if longevity and reliability are your top concerns, then a tough-as-nails steel piston should be right up your alley!

The benefits of a steel piston

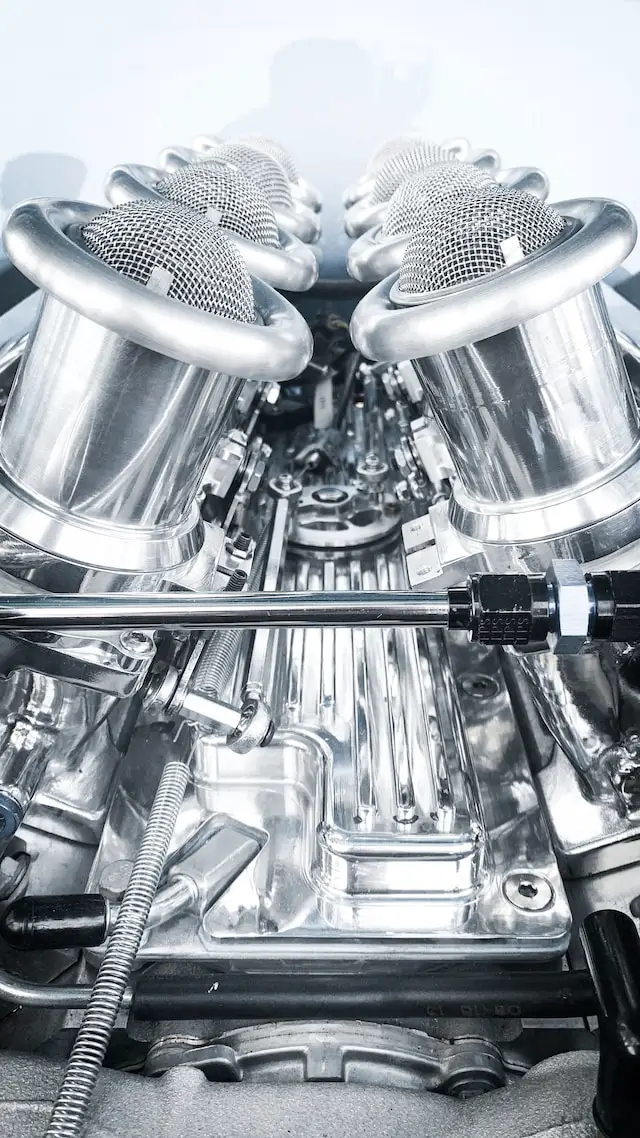

(Photo by Frankie Lopez on Unsplash )

Steel pistons are widely used in disc brake systems due to their durability and strength. Steel is a tough material that can withstand high temperatures and pressures, making it an excellent choice for heavy-duty applications. Here are some of the benefits of using steel pistons:

Firstly, steel pistons have a longer lifespan compared to other materials such as aluminum or phenolic. This means that they require less maintenance and replacement, which can save you time and money in the long run.

Secondly, steel pistons provide better braking performance because they do not expand or contract under heat like other materials do. As a result, they maintain consistent contact with the brake pads, which translates into more efficient stopping power.

Thirdly, steel pistons offer increased safety by reducing the risk of brake failure due to wear or overheating. They also improve overall vehicle handling by providing stable braking control in all weather conditions.

Steel is a recyclable material that has minimal impact on the environment when properly disposed of at end-of-life stage. Thus choosing metal over composite options reduces environmental impacts related to manufacturing process waste disposal.

These advantages make steel piston a popular choice among automotive manufacturers who seek reliability and longevity from their components while meeting sustainability goals through use of eco-friendly materials where possible

The benefits of a phenolic piston

Phenolic pistons are becoming increasingly popular in the automotive industry due to their unique properties. One of the primary benefits of a phenolic piston is its ability to dissipate heat quickly, which can help prevent brake fade during prolonged use.

Another advantage of phenolic pistons is their lightweight construction. The reduced weight allows for quicker acceleration and improved handling, making them an excellent choice for high-performance vehicles.

The use of phenolic material also reduces wear on other brake components such as rotors and pads, improving overall longevity. Additionally, because they don’t rust or corrode like steel pistons do, they require less maintenance over time.

Phenolic pistons also have a lower coefficient of thermal expansion compared to steel ones. This means that they won’t expand or contract with temperature changes as much as metallic materials do, resulting in more consistent brake performance under different conditions.

The benefits of using phenolic pistons are clear: better heat dissipation, reduced weight and wear on other components, increased durability and consistency under varying temperatures. As technology continues to advance within the automotive industry, it’s likely we’ll see even more innovative uses for this versatile material in braking systems.

Which is better?

When it comes to choosing between a phenolic piston and a steel piston, the answer isn’t as simple as one being “better” than the other. Each type of piston has its own unique advantages and disadvantages that make them suited for different situations.

For example, steel pistons are typically stronger and more durable than phenolic pistons. This makes them ideal for high-performance applications where extreme forces and temperatures are involved. Additionally, they can handle higher pressures without deforming or cracking.

On the other hand, phenolic pistons have several advantages over steel pistons in certain circumstances. They’re typically lighter weight which means they put less stress on your braking system overall. They also absorb heat better than metal counterparts which helps prevent damage to brake parts from excessive heat buildup.

Finally, which is better depends on your specific needs and use case scenario. If you’re looking for maximum strength and durability then a steel piston may be right for you. But if saving weight or reducing heat build-up is important then consider going with a phenolic option instead!

How often are disc brakes adjusted by a technician?

When it comes to disc brakes, regular maintenance and inspection are crucial for optimal performance and safety. One element of this maintenance is brake adjustment – ensuring that the brake pads are properly aligned with the rotor.

The frequency at which a technician should adjust your disc brakes can vary depending on several factors, including how often you use your vehicle, driving conditions, and the quality of your braking system components.

In general, it’s recommended that you have your disc brakes checked by a professional mechanic every 12 months or 12,000 miles driven. However, if you notice any unusual noises or vibrations when applying the brakes or if they feel less responsive than usual, it’s best to get them inspected sooner rather than later.

Some other signs that may indicate the need for an adjustment include uneven wear on the brake pads or rotors and excessive brake dust buildup.

In the end staying on top of regular maintenance like brake adjustments can help prolong the lifespan of your braking system while also keeping you safe on the road.

Featured Image By – Ronald Plett from Pixabay