Conduit is a tube-like structure made of metal or plastic used for protecting wiring, PVC is a type of plastic pipe that can be used for various purposes including plumbing, electrical work and more.

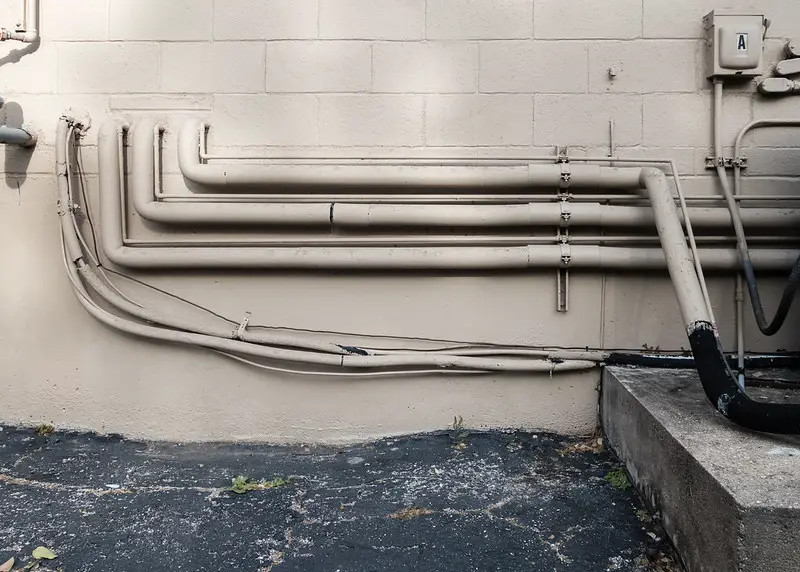

What is conduit?

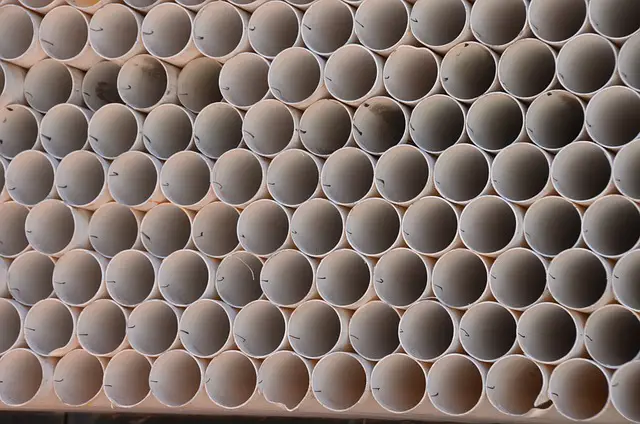

(Photo By smallcurio on Flickr)

Conduit is a type of piping that is used to protect and organize electrical wiring. It can be made from a variety of materials, including rigid metal, flexible metal, or PVC. The primary role of conduit is to keep wires safe from damage by providing a barrier between the wiring and any potential hazards.

One key benefit of using conduit is its ability to prevent electrical interference. This means that the signals within each wire are less likely to interfere with one another when they are running through separate pipes.

Another advantage of using conduit for your wiring projects is that it makes it easier to locate specific wires when you need them. Because all the wires are contained within their own individual pipe, you can easily trace the path of each wire back to its source if necessary.

Conduit provides an important layer of protection for your electrical systems while also making them more organized and efficient.

What is PVC?

PVC stands for Polyvinyl Chloride, a synthetic plastic polymer that is widely used in the construction industry. PVC pipes are commonly used to transport water and other fluids due to its durability and resistance to corrosion.

In addition, PVC is also used in electrical applications as an insulating material for wires and cables. It can withstand high temperatures making it ideal for use in electrical conduits.

PVC has become popular due to its low cost compared to other materials such as metal or concrete. Its lightweight property makes it easy to install and maneuver around tight spaces, reducing installation time and labor costs.

Furthermore, PVC is a versatile material that comes in various sizes, shapes, colors, and thicknesses. This allows builders to customize their projects according to their needs without compromising on quality.

However, like any material, PVC has its limitations too. It may not be suitable for certain environments where extreme temperature changes occur frequently or where exposure to UV light is expected since it can cause discoloration and brittleness over time.

Conduit Vs. PVC – Key differences

Conduit and PVC are often used interchangeably, but they have several key differences. Conduit is a type of metal or plastic tubing that provides protection for electrical wiring, while PVC (polyvinyl chloride) is a type of plastic that is commonly used in plumbing applications.

One of the main differences between conduit and PVC is their durability. Conduit is typically more durable than PVC, making it ideal for outdoor applications where it may be exposed to harsh conditions such as extreme temperatures or moisture. On the other hand, PVC can become brittle over time if exposed to UV rays from sunlight.

Another difference between conduit and PVC is their flexibility. Conduit generally has less flexibility than PVC, which makes it easier to bend and shape around corners or obstacles. However, this also means that conduit may be more difficult to install in tight spaces or areas with limited access.

There are cost considerations when choosing between conduit and PVC. Generally speaking, conduit tends to be more expensive than PVC due to its higher level of durability and strength.

Understanding the key differences between conduit and PVC can help you make an informed decision about which material is best suited for your specific project needs.

When to use conduit?

Conduit is a type of tubing that protects and routes electrical wires or cables. It provides durability, protection against corrosive materials, and can withstand extreme temperatures. So when should you use conduit?

Firstly, if you’re installing wiring in an area where it’s likely to be exposed to physical damage like machinery or vehicles passing by, then conduit is your best choice. Conduit will protect the wiring from getting damaged.

Secondly, if you need to run multiple wires at once or need to add more wires later on, conduit makes it easier than running individual cables.

Thirdly, using conduit ensures compliance with building codes and safety regulations. It also helps prevent fires caused by wire overheating due to poor insulation.

Additionally, when working in hazardous environments such as chemical plants or mineshafts where gas leaks are common occurrences; metal conduits provide extra layers of protection for both personnel and equipment.

Choosing whether or not to use conduit depends on the specific application requirements – but if in doubt about installation standards and safety measures needed for electrical applications – always opt for professional assistance!

When to use PVC?

PVC, or polyvinyl chloride, is a plastic material that has become increasingly popular in construction and electrical installations due to its durability and affordability. Its flexibility makes it an excellent choice for many applications.

One of the primary uses for PVC is as conduit for electrical wiring. This type of PVC is typically gray or white and comes in various sizes depending on the application. It’s lightweight and easy to install, making it an ideal choice for both residential and commercial projects.

Another common use for PVC is in plumbing systems. It’s resistant to corrosion from chemicals found in water, making it a great alternative to metal pipes which can rust over time. Additionally, PVC pipes are often used in irrigation systems because they’re able to withstand high water pressure without leaking.

When planning your next project, consider using PVC if you need a durable and cost-effective solution for conduit or plumbing needs. However, keep in mind that there may be limitations on where you’re allowed to use PVC based on local building codes.

Advantages and disadvantages of conduit

Conduit systems provide a range of advantages. One of the primary benefits is that they offer a high degree of protection for electrical wires and cables. This is especially important when wiring needs to be run through areas where it may be exposed to mechanical damage or moisture.

Another advantage of conduit is its versatility. Conduit can be made from a variety of materials, such as galvanized steel, aluminum, or PVC. This makes it suitable for use in different environments and applications.

In addition, conduit provides a professional appearance and can help keep wires organized and neat. It also allows for easier maintenance and repairs since the wiring can easily be accessed by simply removing the covers.

However, there are some disadvantages to using conduit. The installation process can be more time-consuming than other methods since each section must first be cut to length before being installed. Additionally, conduit takes up more space than other wire management options like raceway or cable trays.

Conduit systems tend to cost more upfront due to materials costs and installation labor costs. However, over time this initial investment may pay off due to lower maintenance requirements compared with less durable alternatives.

While there are some drawbacks associated with conduits such as their higher initial cost and longer installation times; their ability to protect electrical wiring from physical damage make them an ideal choice for industrial settings where safety concerns are paramount

Advantages and disadvantages of PVC

Advantages:

- Cost-effective: Compared to other materials such as metal or wood, PVC is an affordable option.

- Lightweight: PVC pipes and fittings are lightweight, making them easy to transport and install.

- Easy to work with: PVC can be easily cut, shaped, and joined together using adhesives or connectors.

- Corrosion-resistant: Unlike metals that can corrode over time due to exposure to moisture or chemicals, PVC is corrosion-resistant.

Disadvantages:

- Not suitable for high temperatures: While PVC has good chemical resistance properties, it may not withstand high temperatures well. This makes it unsuitable for certain applications where heat resistance is required.

- Environmental concerns: The production of PVC involves the use of toxic chemicals that can have harmful effects on the environment. Additionally, when burned or disposed of improperly, it can release toxins into the air and soil.

- Brittle in cold temperatures: When exposed to cold temperatures for extended periods of time, PVC pipes can become brittle and more prone to breaking.

While there are some drawbacks associated with using PVC material in construction projects or other applications – its cost-effectiveness and versatility make it a popular choice among professionals.