Casework is pre-fabricated cabinets or storage units, while millwork refers to custom-made woodwork produced in a mill or woodworking shop.

TL;DR Casework Vs. Millwork

Casework refers to pre-made cabinets and storage units that are typically mass-produced in a factory setting. Casework is commonly used in commercial spaces such as offices, hospitals, and retail stores.

On the other hand, millwork involves custom-made woodwork created specifically for a particular space or project. Millwork is commonly found in residential settings such as kitchens, bedrooms, and living rooms.

What is casework?

Casework refers to the construction and installation of cabinets, shelves, and other built-in storage units within a building. It is typically created off-site in a workshop or factory, then transported and installed at the desired location. Casework is often made from materials such as wood, laminates, or metal.

What is millwork?

Millwork refers to the customized woodwork or carpentry that is created in a mill or workshop. It involves the crafting and installation of architectural elements such as doors, windows, moldings, paneling, and cabinetry. Millwork is often used to enhance the design and functionality of buildings, adding a touch of elegance and sophistication.

Casework Vs. Millwork – Key differences

| Aspect | Casework | Millwork |

|---|---|---|

| Definition | Pre-fabricated cabinets or storage units | Custom-made woodwork produced in a mill or woodworking shop |

| Type of Production | Mass-produced and standardized | Custom-made and tailored to specific projects |

| Material Usage | Often made from manufactured boards and veneers | Primarily uses solid wood and high-quality materials |

| Design Flexibility | Limited design options due to standardized production | Highly customizable and adaptable to unique designs |

| Application | Commonly used in commercial and residential settings | Mainly used in custom projects, including architectural elements and furniture |

| Installation | Requires assembly and installation on-site | Installed as a finished product after manufacturing |

| Cost | Generally more cost-effective | Often more expensive due to custom nature and higher-quality materials |

| Lead Time | Shorter lead time for availability | Longer lead time for custom manufacturing |

Examples of casework

- Kitchen Cabinets: Pre-fabricated cabinets used for storing dishes, utensils, and food in kitchens.

- Bathroom Vanities: Pre-made cabinets with sinks and storage for bathrooms.

- Office Furniture: Desks, file cabinets, and storage units in commercial settings.

- Classroom Storage: Cabinets and shelves used in educational institutions to organize supplies.

- Retail Display Cases: Cabinets and showcases used in stores to display merchandise.

- Built-In Bookshelves: Pre-fabricated bookshelves designed to fit specific spaces in homes or offices.

- Laundry Room Storage: Cabinets and shelves for organizing laundry supplies and cleaning products.

Casework is commonly found in both residential and commercial settings and is chosen for its cost-effectiveness and standardized design options.

Examples of millwork

- Custom Cabinetry: Tailor-made cabinets, wardrobes, and storage units designed to fit specific spaces and requirements.

- Crown Molding: Decorative trim installed at the junction between walls and ceilings to add elegance to a room.

- Window and Door Casings: Custom-made frames that surround windows and doors for a seamless and aesthetic look.

- Custom Wood Paneling: Intricately designed wooden panels used for wall coverings or wainscoting.

- Custom Built-In Furniture: Custom-designed furniture pieces integrated into a specific space, such as bookshelves or window seats.

- Architectural Columns: Custom-designed columns used for decorative or structural purposes in buildings.

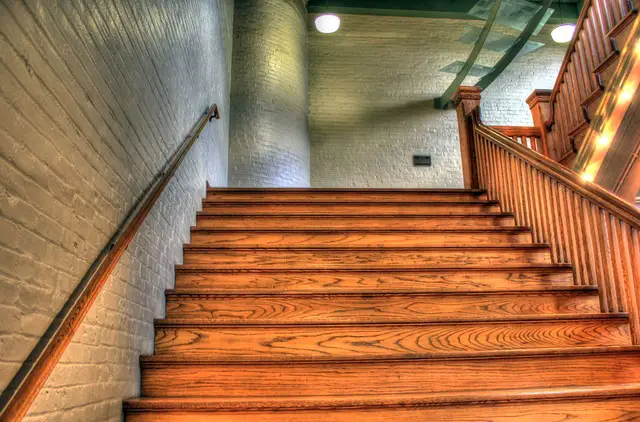

- Staircases and Railings: Custom-made staircases and handrails crafted to match the style of the space.

Millwork is highly versatile and offers unique design options as it is customized for individual projects, adding a personalized and sophisticated touch to interior and exterior spaces.

Advantages and disadvantages of casework

Advantages of Casework

- Cost-Effective: Casework is generally more affordable than custom-made millwork, making it a budget-friendly option for various projects.

- Quick Availability: Casework is mass-produced and readily available, allowing for faster project completion.

- Standardized Design: Casework comes in standardized sizes and styles, making it easier for contractors and designers to plan and install.

- Ease of Installation: With pre-fabricated pieces, casework installation is relatively straightforward and requires less time on-site.

- Consistent Quality: As casework is produced in controlled environments, it maintains consistent quality and finish.

Disadvantages of Casework

- Limited Customization: Casework design options are limited, which may not suit unique or specific project requirements.

- Design Repetition: Due to mass production, casework can be commonly seen in various buildings, leading to less originality in design.

- Quality Variability: While consistent, casework may not always match the level of craftsmanship found in custom millwork.

- Space Constraints: Standard sizes may not fit irregular or challenging spaces, potentially leading to wasted space or awkward gaps.

- Aesthetics: Some designers and clients may find casework lacking the elegance and bespoke charm of custom millwork.

Advantages and disadvantages of millwork

Advantages of Millwork

- Customization: Millwork offers complete customization, allowing designers and clients to create unique, tailor-made pieces that precisely fit the project’s requirements and design vision.

- High-Quality Craftsmanship: Millwork is crafted by skilled artisans and carpenters, resulting in superior quality and attention to detail.

- Unique Aesthetics: Custom millwork adds a distinct and luxurious feel to interior and exterior spaces, elevating the overall aesthetics.

- Flexibility in Design: Millwork can adapt to irregular spaces, making it ideal for projects with challenging architectural features.

- Long-Term Value: Well-crafted millwork can increase the property’s value and appeal, offering a lasting investment.

Disadvantages of Millwork

- Higher Cost: Custom millwork is typically more expensive due to the labor-intensive process and premium materials used.

- Extended Lead Time: Custom millwork requires design, production, and finishing, leading to longer project timelines.

- Skilled Labor Required: Proper execution of millwork necessitates experienced and skilled craftsmen, which can be limited in availability.

- Maintenance: Intricate millwork may require regular maintenance and care to preserve its beauty and functionality.

- Limited Availability: Millwork is unique to each project, making it challenging to replicate in other locations or future projects.

Image Credits

Featured Image By – ginsburgconstruction from Pixabay

Image 1 By – StockSnap from Pixabay

Image 2 By – Yinan Chen from Pixabay